If you need to pack 20,000 items and sort them for shipment into individual orders, you'll need dozens of employees who will spend their days performing routine tasks and making mistakes. And if you also have to track new arrivals and generate reports for each container, you're likely to drown in paperwork.

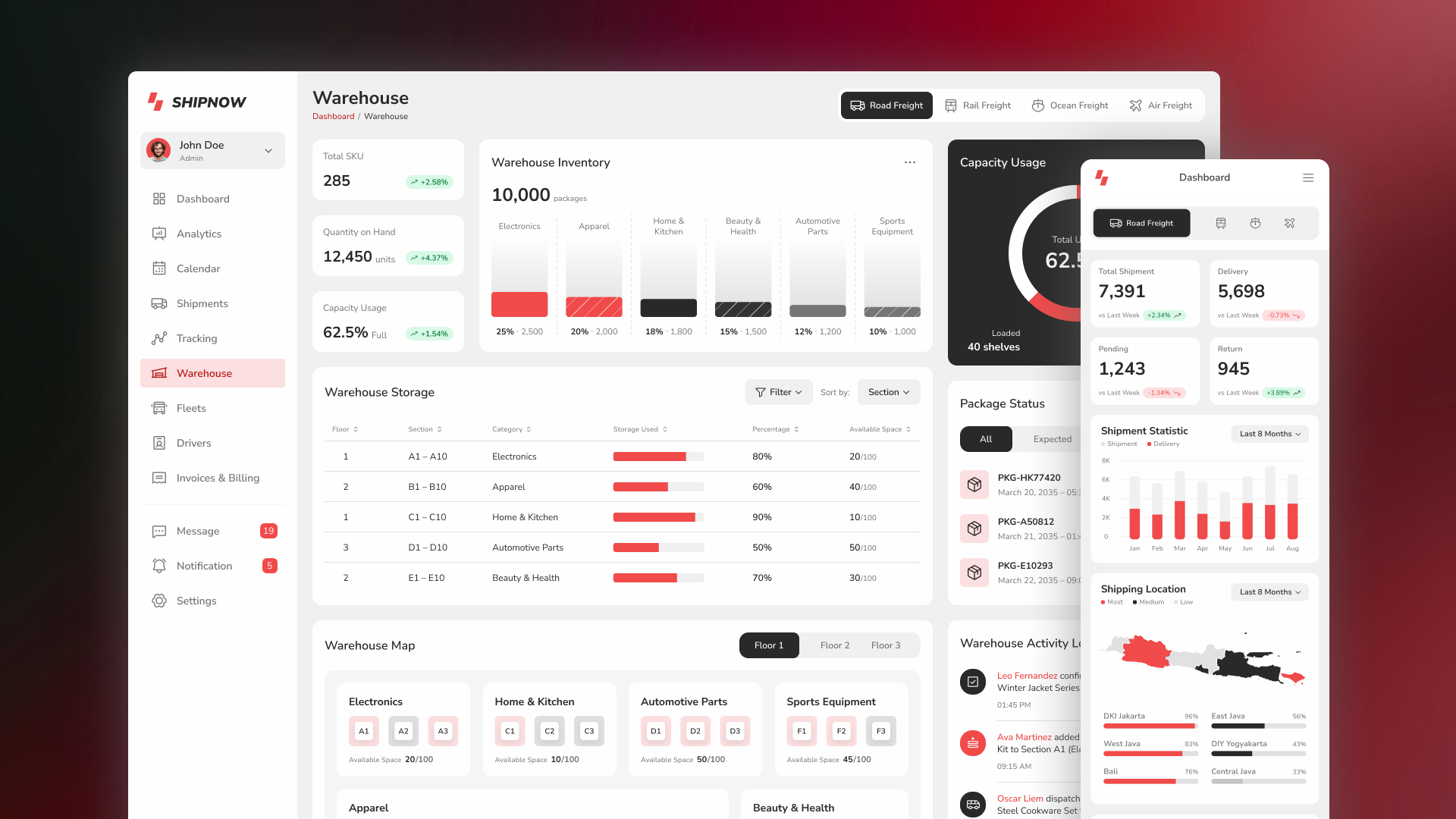

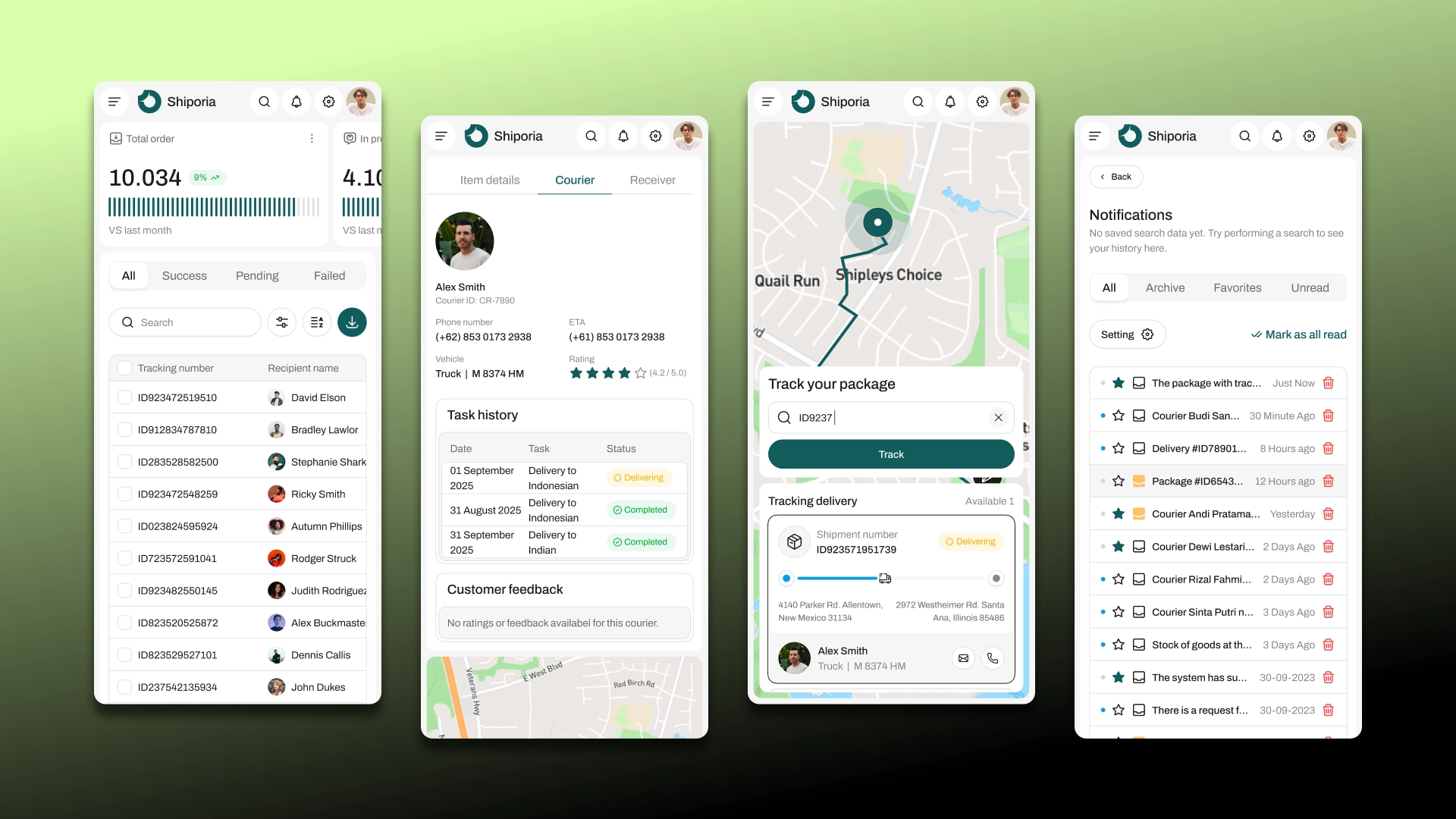

There's a choice here. Continue to operate at full capacity year after year, or take a different path — automating the warehouse using modern technology. Automation in this area often evokes a slight fear, as images of robots and other high-tech tools immediately spring to mind. In fact, this isn't always the case. Much more often, specialized software — warehouse management systems (WMS) — is used for this purpose. Implementing them requires much less investment and helps optimize most processes.

In this article, we'll explain how to automate warehouse logistics from scratch and what practical benefits this brings to businesses.

Benefits of warehouse automation

As we know, logistics begins in the warehouse, which means supply chain modernization should begin there. Let's take a look at the benefits this will bring to the company.

Refusal of manual work

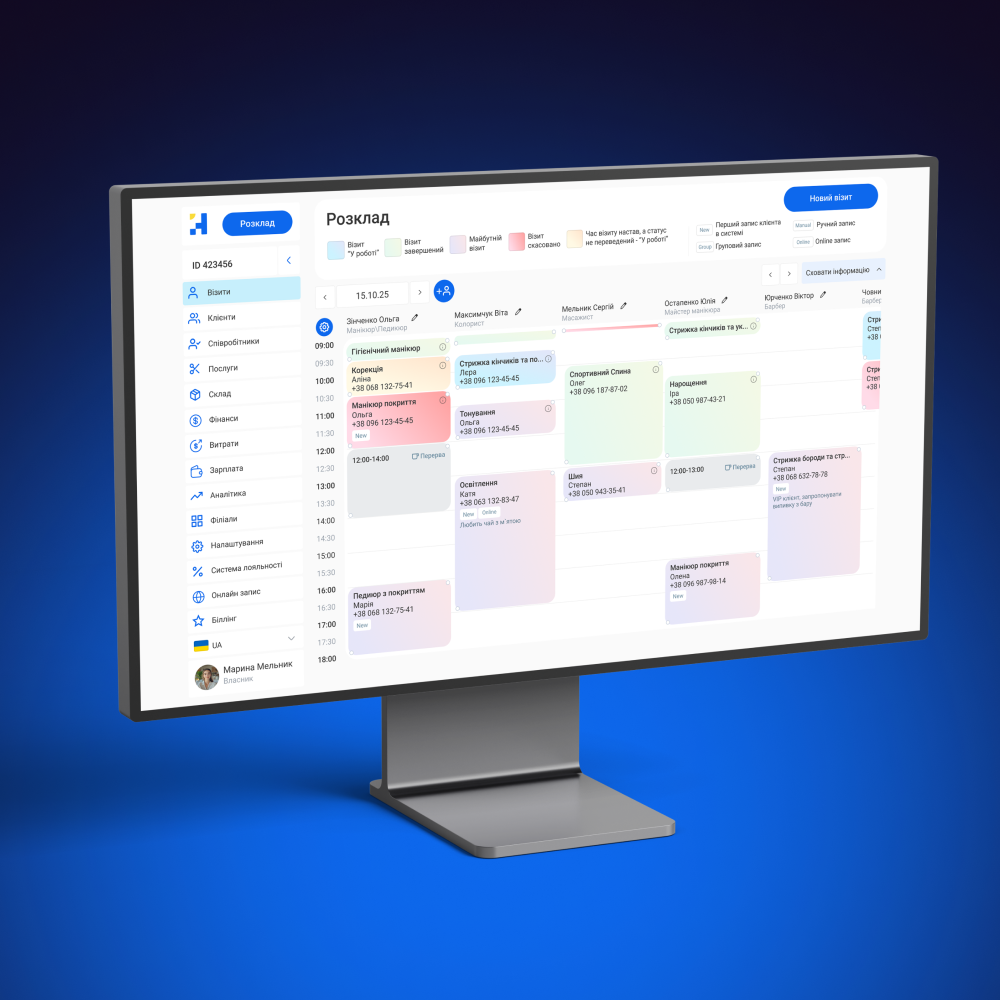

The implementation of technology allows for a minimal workforce and the digitalization of routine tasks. As a result, businesses free up resources previously needed for payroll and eliminate headaches such as labor shortages, seasonal employment, and sick leave.

Optimization of warehouse space

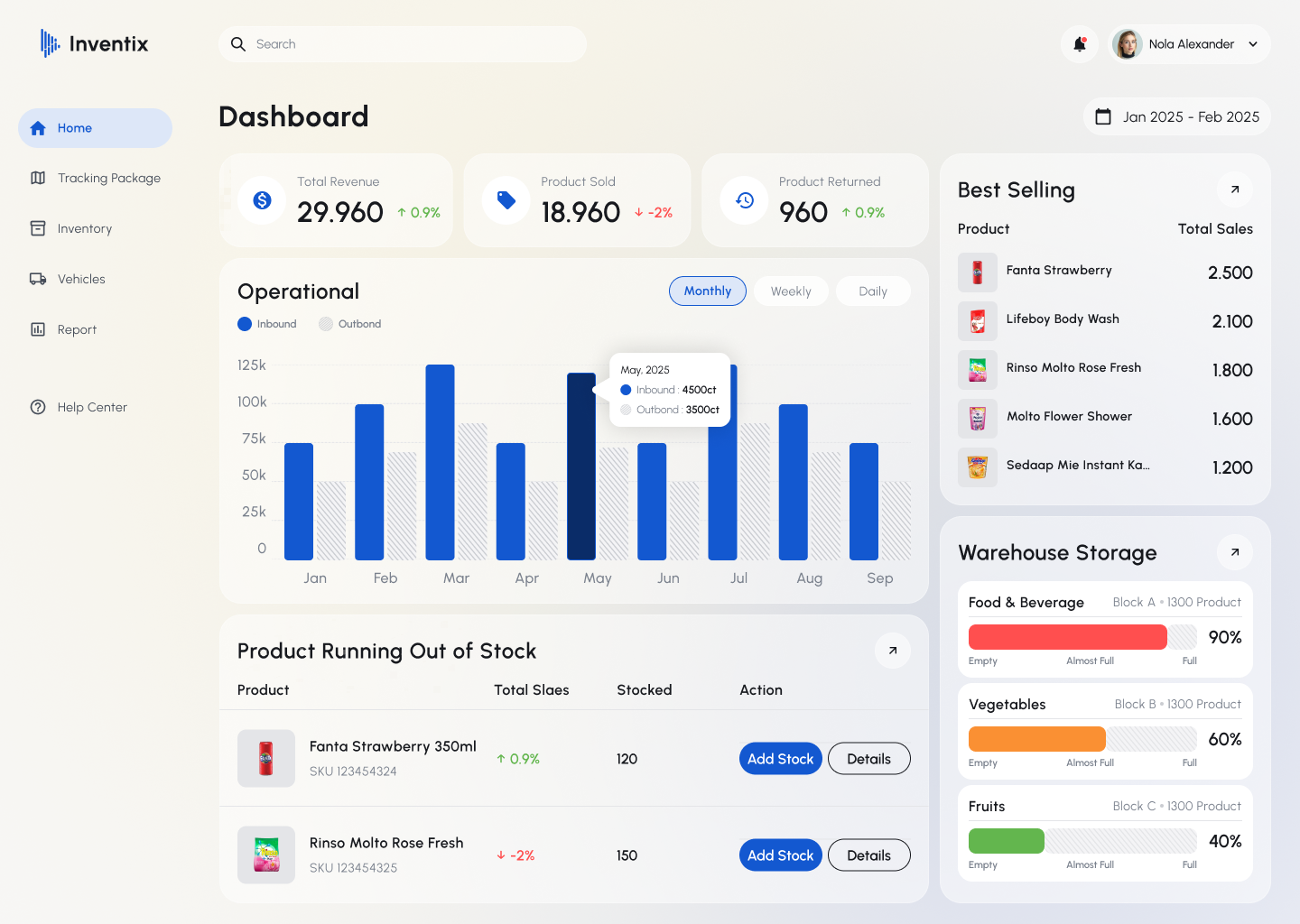

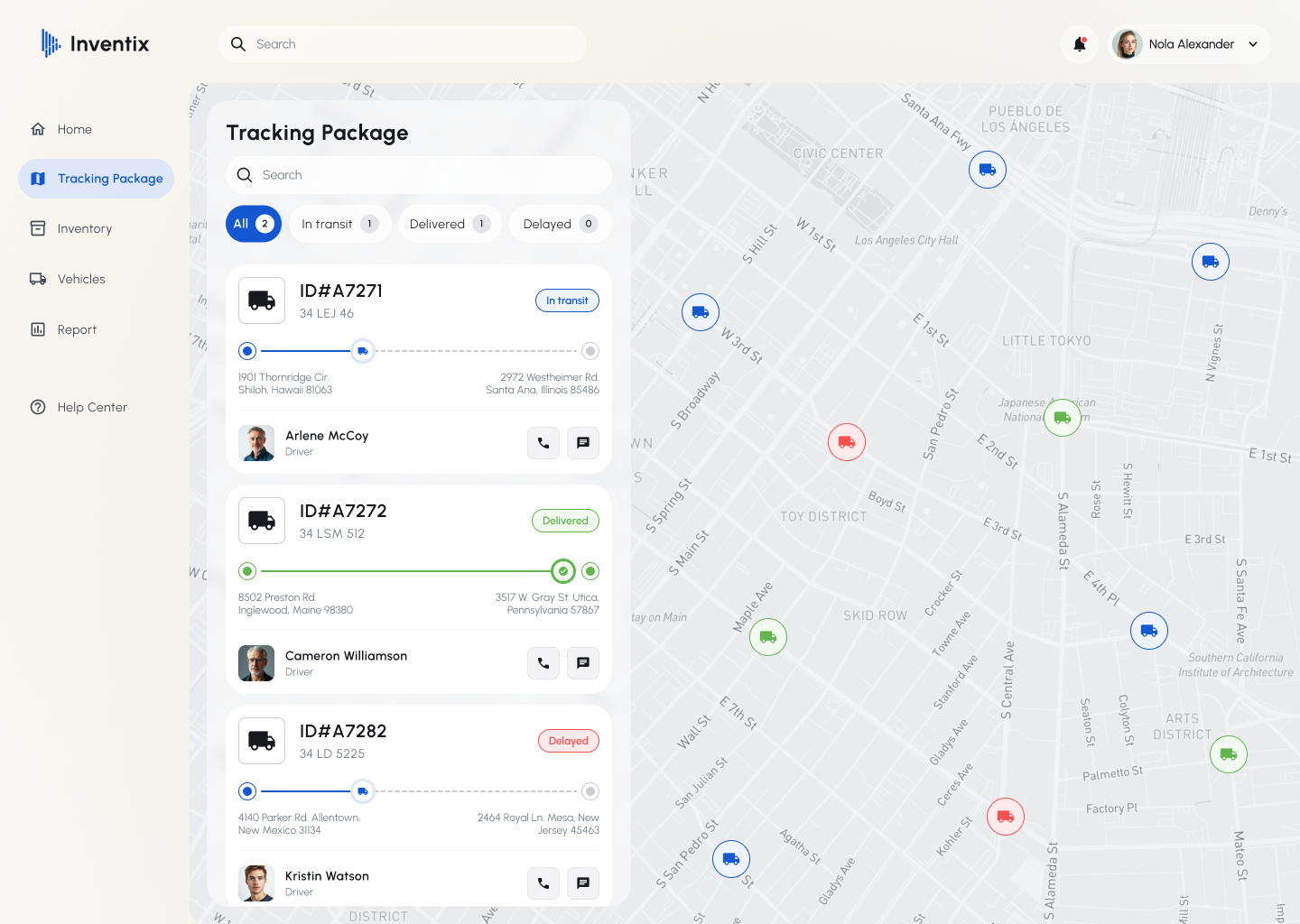

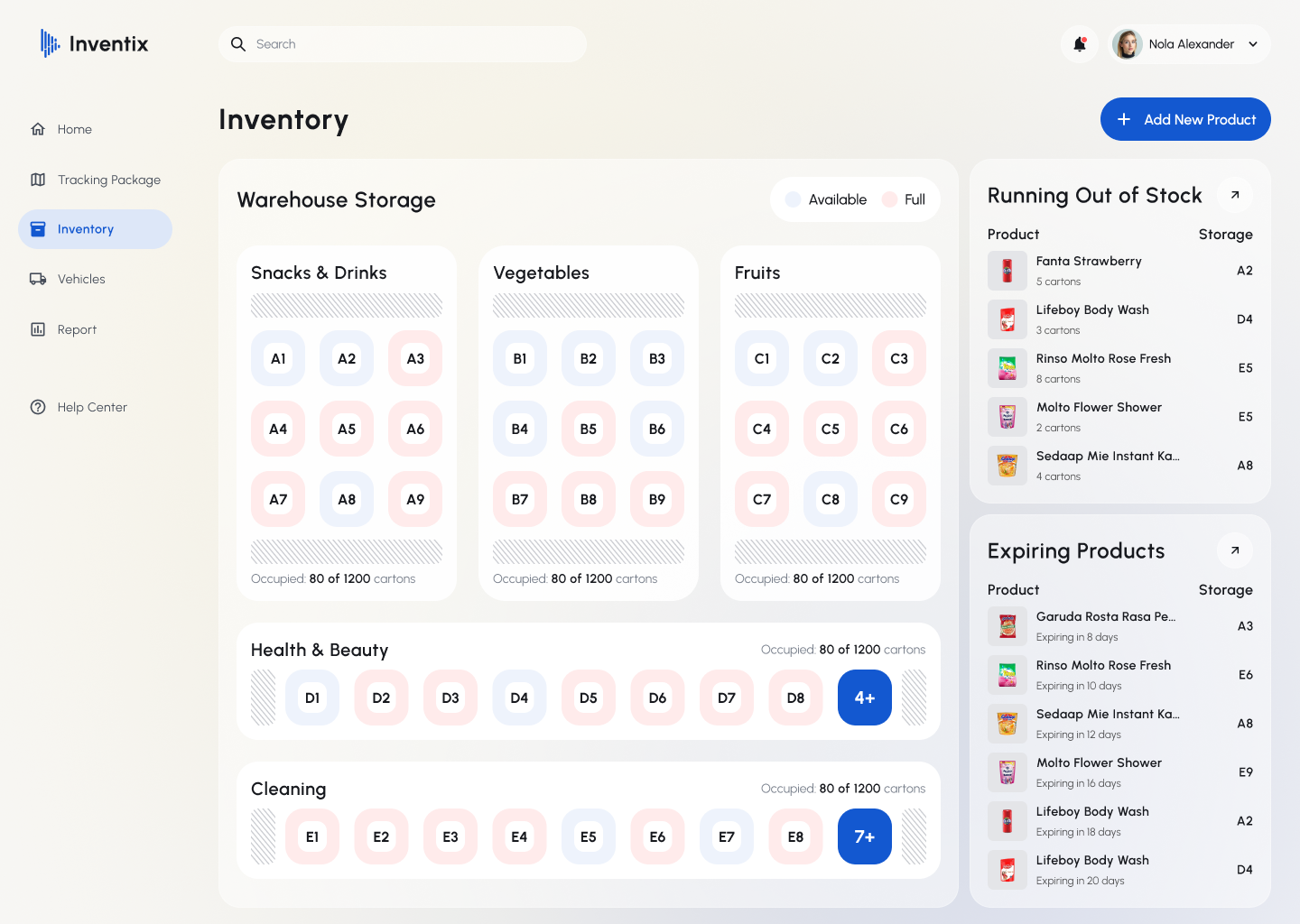

The analytical capabilities of a WMS, especially when combined with specialized equipment, allow for the most efficient use of every square meter of warehouse space. The software will help with efficient space planning, while forklifts, stackers, and robots will make the warehouse more vertical, significantly increasing storage density. Crucially, the WMS organizes products based on rotation time and frequency, eliminating congestion and docking issues.

Improving the efficiency of goods acceptance and inspection

Upon arrival at the warehouse, goods are subject to a thorough inspection: to ensure they comply with documentation and completeness, are free of damage, and so on. Employees spend a considerable amount of time and effort performing these tasks. Furthermore, the manual approach does not eliminate the possibility of human error.

A WMS allows for fully automated and accelerated warehouse receipt verification, while minimizing errors. To achieve this, the system utilizes automated weighing systems, computer vision, and artificial intelligence capabilities. This means human intervention is only required when necessary.

Increase in turnover of goods

Automation with a WMS enables comprehensive warehouse planning, accelerates internal processes, promptly reduces the amount of unsaleable products, and increases inventory as demand increases. Taken together, this has direct positive consequences for the business:

- Improving the quality of service.

- Improving customer experience.

- Stable availability of in-demand products.

- Improving working conditions in the warehouse.

As a result, product turnover and business profitability increase.

How to automate a warehouse from scratch

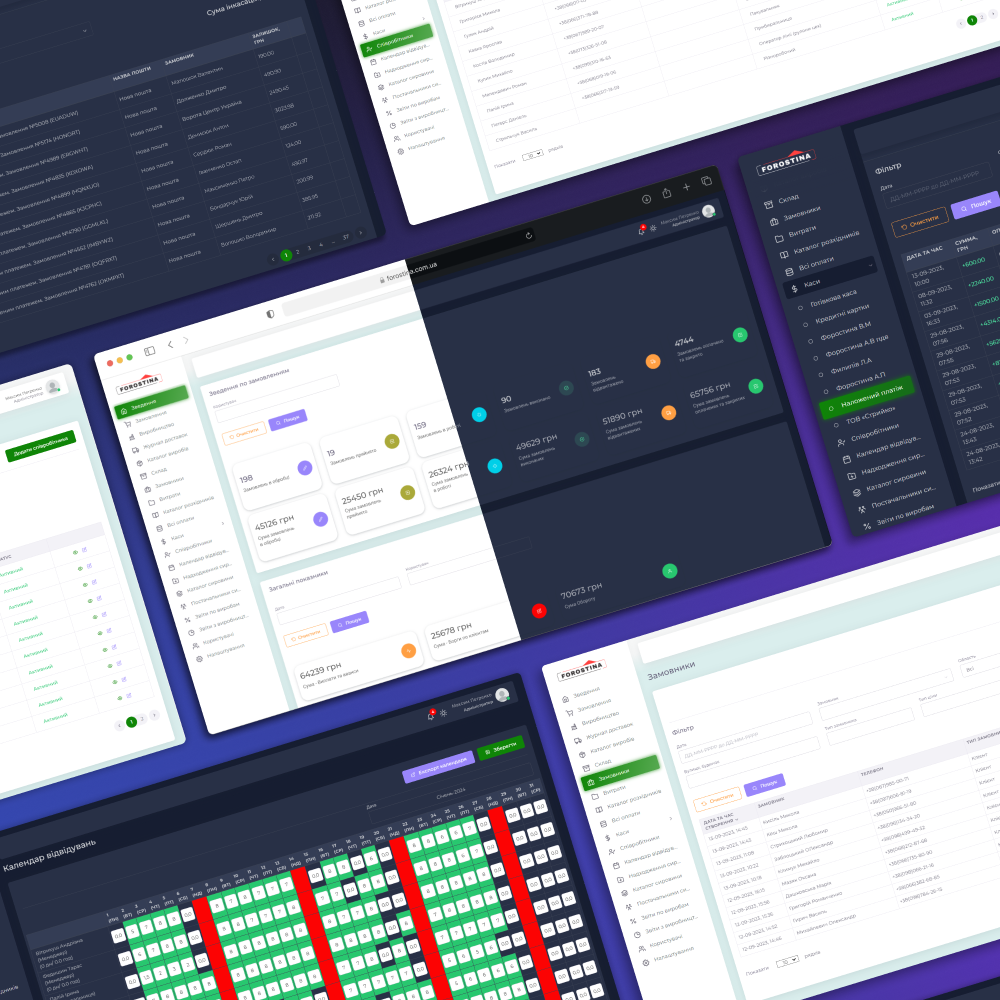

Implementing a WMS system to automate warehouse logistics is a complex task that requires careful assessment and preparation. The complexity and cost of such a solution will directly depend on the size of the business, its objectives, and growth goals.

In other words, you will need a clear action plan, which we have briefly described below:

- Warehouse analysis. It's important to note that simple figures about square footage and throughput won't be enough to provide a complete picture. Warehouse performance depends on dozens of different factors, including the experience of managers, the specifics of working with contractors, the size of the workforce, and so on. Therefore, a more in-depth audit is required.

- Defining goals and objectives. Having a complete understanding of warehouse operations, it's possible to determine the key goals and objectives of automation. This means determining what specific problems the WMS will solve. For example, this could include eliminating bureaucracy, speeding up processes, increasing warehouse space efficiency, etc. There are many options here.

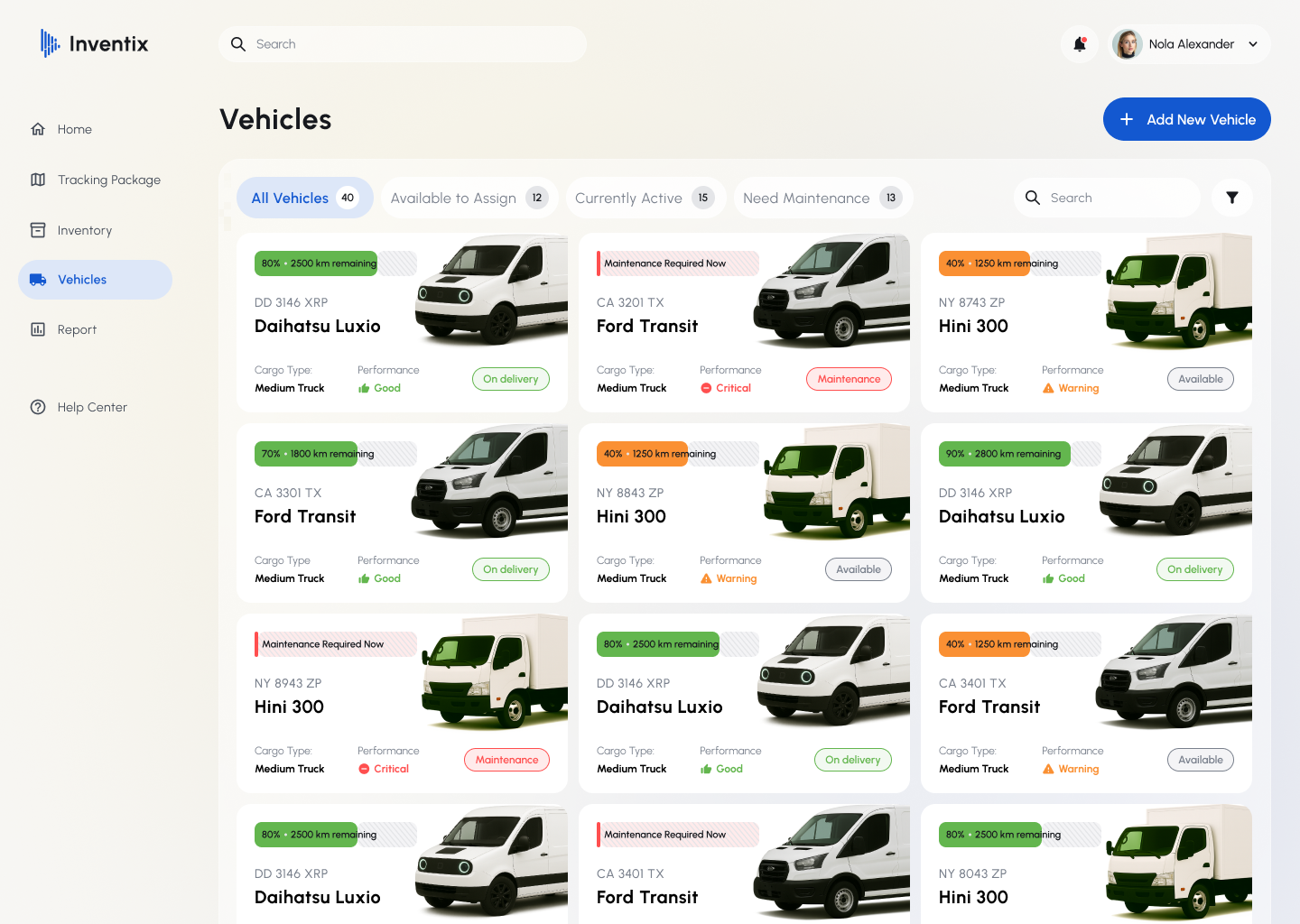

- WMS Development and Warehouse Setup. When digitalizing a warehouse from scratch, you'll likely need to not only create a WMS platform but also ensure the physical setup of the warehouse with the necessary tools — from barcode scanners and additional CCTV cameras to conveyors and autonomous forklifts. As we've already discussed, everything depends on the business's goals and priorities.

- Staff training. You likely won't be able to migrate your entire operation to a WMS overnight and begin using the corresponding physical tools effectively. Therefore, it's best to begin staff onboarding early, during the integration phase.

- Platform launch. The WMS is created and deployed, the equipment is installed, and the staff is trained. From this point on, the business will begin to operate in a new way. But that's not the end. Next comes the product support and development phase, with the elimination of any remaining bugs and inaccuracies. This ensures the platform grows and develops alongside your business, and its functionality remains relevant over time.

Automating Warehouse Logistics with AvadaCRM

AvadaCRM has been developing comprehensive solutions for logistics automation for over 10 years. By contacting us, you can benefit from the experience and practical skills of the industry's strongest teams.

We'll help you find unique technical solutions for your company and provide expert support at every stage of WMS implementation — from warehouse analysis to platform implementation and ongoing support.

FAQ

-

What is a WMS system and what warehouse processes does it automate?

WMS (Warehouse Management System) is warehouse management software that automates the receiving, storage, picking, inventory, and shipping of goods. The system minimizes manual work, reduces errors, and provides complete control over warehouse operations in real time.

-

Is warehouse logistics automation suitable for small and medium businesses?

Yes, automation is relevant not only for large warehouses. Modern WMS solutions are scalable to business needs and can be implemented in stages, allowing for cost optimization and rapid results, even for small and medium-sized businesses.

-

How long does it take to implement a WMS in a warehouse from scratch?

The implementation timeline depends on the warehouse size, the complexity of the processes, and the scope of integrations. On average, a project can last from several weeks to several months, including audit, development, configuration, staff training, and system launch.

-

What are the main costs associated with warehouse automation and what do they depend on?

The cost of automation depends on the WMS functionality, the need for integration with other systems, the scope of customization, and the use of additional equipment (scanners, cameras, weighing systems, conveyors). Compared to full warehouse robotization, software-based automation is significantly more affordable.

-

Is it possible to integrate WMS with ERP, CRM and other business systems?

Yes, WMS easily integrates with ERP, CRM, accounting, and logistics systems. This ensures a unified information space, automatic data exchange, and transparency of all business processes.

-

What results can be expected from warehouse automation in the first months after launch?

Even at the initial stage, businesses experience reduced errors, faster warehouse operations, better inventory control, and increased inventory turnover. In the long term, this positively impacts service, profitability, and scalability.